The computer radiator is a device used to reduce the internal temperature of a computer, typically consisting of radiator, fans, and cooling water.

The function of a PC radiator is to transfer the heat generated by the computer CPU to the external environment through convection, radiation, and conduction,

thereby protecting the computer hardware and software from overheating damage.

The performance and efficiency of computer radiator depend on various factors, such as the material, structure, size, fan speed, and water cooling system flow rate of the radiator.

The selection and installation of PC radiator should be reasonably designed and adjusted based on the purpose, configuration,

and usage environment of the computer, in order to achieve the best heat dissipation effect.

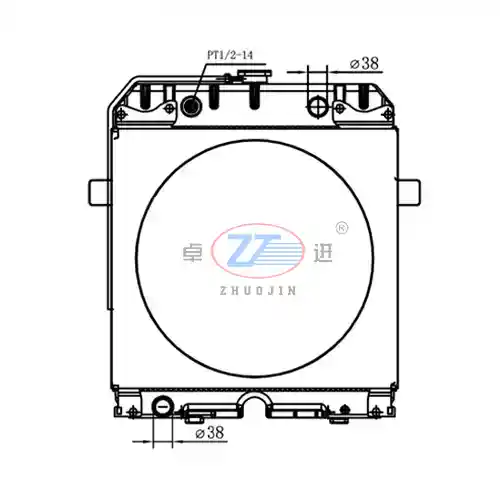

PC radiator parameter

| name | parameter |

| Material | aluminum |

| Thread | G1/4 threaded port |

| Core size | 120×109×16mm |

| specifications | Ø 9.5mm pagoda outlet |

| Surface treatment process | black spray plastic anti-corrosion treatment |

| Sealing process | nitrogen protection brazing |

| fins | 13 pcs |

| Boundary dimension | 161.5×119× 32mm |

| Fin specification | 16×7mm |

| Heat sink density | 16 fold/inch |

| Fan installation size | W105 ± 0.5mm H105 ± 0.5mm |

computer radiator production process

This is a brazing process for computer radiators, and the entire production process is as follows

1, Production of fins

The radiator factory purchases aluminum foil with a width that matches the radiator,

uses a fin machine to roll and shape the fins of the radiator, and places them in a box for further use

2, Production of aluminum tubes

The price of machines for producing aluminum tubes is relatively expensive, and some factories directly purchase pipes that meet the size of the radiator

3, Production head plate

This is a simple stamping production process, which only requires the production of a dedicated head plate mold. The produced head plate is cleaned by ultrasonic waves and then waiting for the next step of use

4, Core assembly

Assemble the aluminum tube, fins, and head plate into the core of a PC radiator, which requires a dedicated core assembly machine

5, Aluminum brazing

This is a fully automated aluminum brazing process, which is also the most critical step in the entire production of computer radiators.

and it is also the most technically challenging. When the entire product is welding and goes through the next step.

6, Sealing test

When the radiator is welding, it needs to undergo a leak test.

7, Surface treatment

Some computer radiators need to be spray with black paint.

8, Testing and Packaging

All radiators need to undergo strict installation size testing before packaging them

The entire production process ends here

wechat

wechat